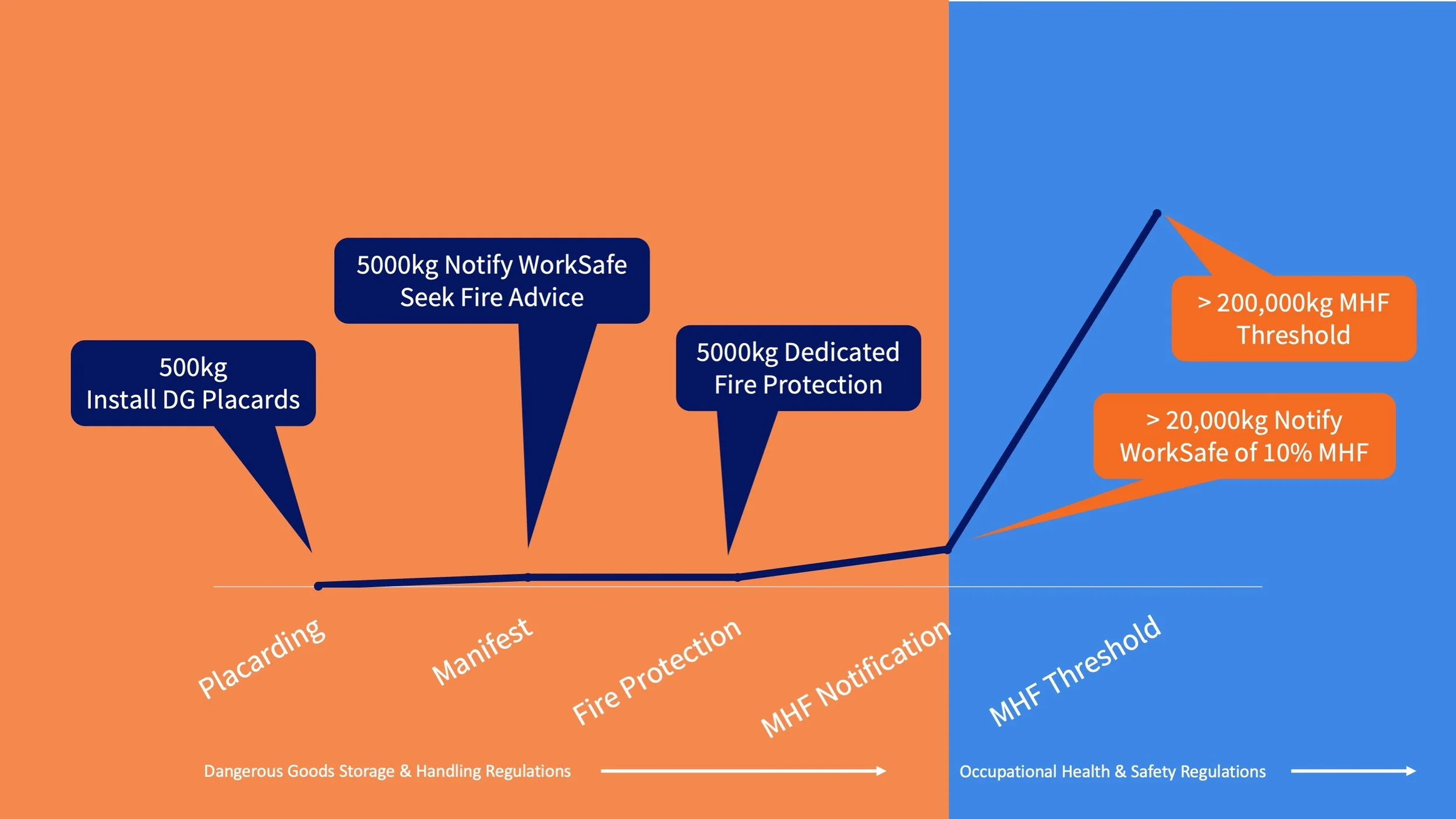

The Dangerous Goods Continuum

Discussion about dangerous goods regulation is often punctuated with references to Schedule 2, Schedule 4, Schedule 14, Schedule……

What does it all mean? and where is the intersection of dangerous goods storage and handling regulation made under the Dangerous Goods Act 1985 (Vic) and major hazard regulation made under the Occupational Health and Safety Act 2004 (Vic).

Whilst regulation of dangerous goods might be centralised in the future (read more about Victoria’s dangerous goods legislative review here), there remains two Acts and five sets of regulation which cover dangerous goods in the state of Victoria.

This article seeks to effectively demonstrate how the regulation of dangerous goods exists on a risk-based continuum.

As the volume of a particular dangerous good is increased and a series of thresholds are passed, the regulatory obligations increase on the person who is storing the dangerous goods (referred to as an “occupier”). These thresholds are contained in Schedule 2 of the storage and handling regulations and Schedule 14 of the major hazard regulations.

The Dangerous Goods Continuum: Thresholds for LPG Shown.

Understanding these thresholds is critical to ensuring you’re compliant but more importantly you’re minimising your dangerous goods inventory and risk on site (referred to as a “premises” in the legislation) which has a secondary benefit of avoiding additional layers of regulation.

For the purposes of this article, we’ll examine liquified petroleum gas (LP Gas or LPG as it is commonly known). LPG is both a dangerous good (listed in the Australian Dangerous Goods, the ADG Code) and a Schedule 14 material (more on that later).

Placarding

The first threshold is “placarding”, occupiers who store and handle dangerous goods above placarding quantities must have warning placards installed. Placarding is commonplace and provides a visual warning of dangerous goods at a premises for emergency services. The requirement for placarding includes the red and white ‘HAZCHEM’ outer warning placards at site vehicle entrances.

In our example, storing 500kg of LPG triggers the need for a Class 2.1 placard at the storage location in addition to ‘HAZCHEM’ outer warning placard(s).

Manifest

The second threshold is “manifest”, the purpose of a dangerous goods manifest is to provide first responders with information about the quantity, type and location of dangerous goods stored and handled on the premises. The manifest is commonly kept in the “red box” at the front of a premises. It’s important that this information is not “set and forget” but reviewed regularly to account for changes that inevitably occur.

Schedule 3 of the storage and handling regulations stipulates the information required to be contained within the dangerous goods manifest, in summary the manifest needs to include:

The name of the occupier

The address

The date when the manifest was prepared or last revised

At least two emergency contacts

A summary table of dangerous goods stored by class and packing group

A detailed listings of packaged and bulk dangerous goods stored including those in manufacture

A site plan showing storage locations and emergency information

The manifest needs to be concise and should avoid unnecessary and excessive information to ensure the emergency services are able to respond to incidents in a timely and appropriate manner.

Don’t be misled, the obligations do not end with a manifest; occupiers who store dangerous goods above manifest quantities have additional and specific obligations including:

Preparing an emergency plan;

Seeking written advice from the emergency services on the emergency plan;

‘Having regard to’ the written advice of the emergency services; and

Notifying WorkSafe at least every two years (unless there’s been changes at the premises, see our article here for more information on notification)

Despite the common misconception, dangerous goods notification is an administrative process and does not constitute a licence or approval from WorkSafe. However, you can expect that the information provided will be used to create a risk profile of the premises and inform compliance activity, so it’s prudent to ensure all the above-mentioned steps are taken when submitting notification.

Returning to our example, storing 5000kg of LPG triggers the need for a dangerous goods manifest, an emergency plan and WorkSafe notification.

Fire protection

The third threshold is fire protection, not to be confused with general fire protection such as extinguishers and fire hose reels that may be installed for general protection. This obligation is for a dedicated fire protection system which is designed and constructed for the types and quantities of dangerous goods at the premises. The nature of the fire system is not prescribed in the regulation; for this Australian Standards such as AS/NZS 1596:2002 The storage and handling of LP Gas can be helpful in providing further specific guidance.

In the case of 5000kg of LPG the fire protection quantity is the same as the manifest threshold, however, this is not always the case and Schedule 2 of the storage and handing regulations should be consulted.

Major Hazard Facility Notification (>10%)

In Victoria the types and volumes of dangerous goods which trigger the MHF obligations are defined in Schedule 14 of the Occupational Health and Safety Regulations 2017 which is distinct from the Dangerous Goods Storage and Handing Regulations 2022.

Similar to the framework within the storage and handing regulations, the MHF threshold for any given material can vary significantly depending on the material’s inherent risk, for example the MHF threshold for extremely hazardous materials could be as low as 100kg while the threshold for less hazardous material could be as high as 50,000 tonnes.

Schedule 14 materials are identified in two ways:

Explicit and specific reference to the material in Table 1 of Schedule 14 with an individual (risk-based) MHF threshold set for the material

A more general or generic reference to particular chemical characteristics via GHS classification

LPG is listed in Table 1 of Schedule 14 with a threshold of 200 tonnes therefore, to reach the MHF notification requirement, the LPG storage would need to increase significantly to greater than 20,000kg (but less than 200,000kg). In this situation, occupiers need to notify WorkSafe that they’re storing or a likely to store more than 10% of the MHF threshold. The specific information required in the notification is described in Schedule 18 of the occupational health and safety regulations. Upon notification, WorkSafe has the ability to determine whether the premises shall be deemed an MHF and required to conform with the MHF regulations, including obligations such as:

Comprehensive hazard identification and risk assessment

Safety management system

Detailed emergency planning

Performance monitoring

A Safety Case which demonstrates compliance with the regulation and risk management

Major Hazard Facility

200,001kg of LPG would impose the MHF regulations automatically, there is no discretion of the regulator. In Victoria there’s approximately 40 MHFs under Victorian legislation (excluding the small number of federally regulated MHFs which also exist in Victoria). A list of current MHFs can be found here.

Importantly, whilst MHFs are exempt from some administrative obligations such as storage and handling notification, most other obligations under the dangerous goods legislation operate in parallel to the major hazard regulations.

While the example of LPG is a relatively simple one, more often than not a single dangerous good isn’t stored in isolation. For example, a manufacturing facility or dangerous goods warehouse may have multiple materials with different individual thresholds. In these circumstances it’s important to closely examine the Schedules and seek specialist advice if required.

Conclusion

Reducing the volume of dangerous goods on site reduces the inherent risk posed by the goods. Elimination not only makes sense from a risk management perspective but also reduces the regulatory burden on facility operators. Practical steps occupiers can take include:

Substituting dangerous goods which have lower thresholds (i.e. more hazardous) with those that have a higher threshold (less hazardous)

Storing materials off-site at reputable DG warehouses that may already have fire protection and/or a MHF licence for example

Reducing volumes of waste dangerous goods (see our article on dangerous goods waste here)

Regardless of the quantity of dangerous goods there’s a need to reduce risk so far as is reasonably practicable (SFAIRP) when storing and handling dangerous goods. What is considered SFAIRP will depend on a number of factors including the nature of the hazard and industry practice. Our article A workplace Safety Inspector visits what now? discusses the concept of SFAIRP further.

If your unsure about where your site is on the dangerous good continuum, MicroRisk Group can assist you with a regulatory compliance plan. See our Services for more information.